Project Details

- Category Gold Tester

- Date November 11, 2021

- Client Name Lawrence Hilliard

- Budget $2150.00

- Project Manager John Doe

- Location New York, USA

- Website AI-Lab.Com

- rating

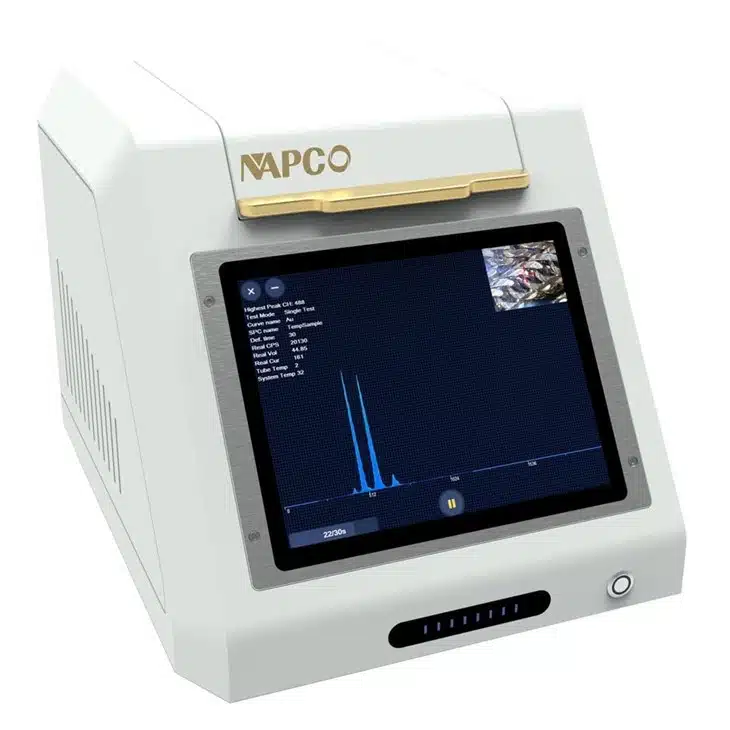

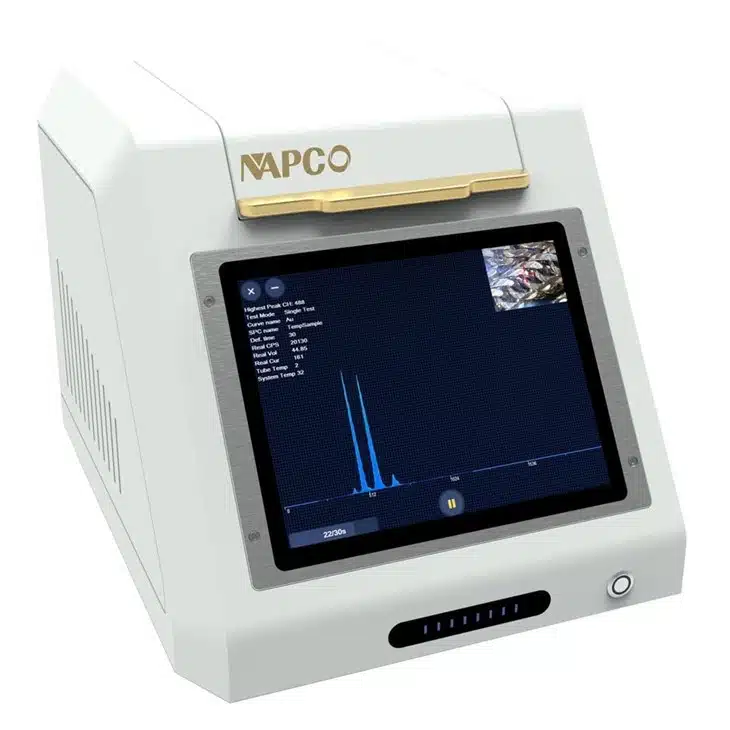

N1-25 XRF Gold Tester

The N1-25 is Napco’s best-selling compact benchtop XRF analyzer, engineered for jewelry shops, pawnshops, banks, and small-to-medium refineries that demand maximum accuracy in minimum space.

Why thousands of professionals choose the N1-25 every day:

- 99.99%+ accuracy – matches or exceeds large laboratory systems

- 30-second full analysis – instant karat ID and elemental breakdown

- World’s smallest footprint – only 35 × 30 × 35 cm, fits on any counter

- Non-destructive – test finished jewelry, coins, bars, or scrap without damage

- Detects all common frauds: plating, tungsten-filled bars, cadmium/iridium inclusions, under-karated gold

- Analyzes 25 elements simultaneously (Au, Ag, Pt, Pd, Rh, Ru, Cu, Zn, Ni, Cd, Fe, Co, Ir, etc.)

- Smart auto-karat classification (8K–24K gold, 800–999 silver, etc.) with color-coded results

- Built-in HD camera – live view of exact testing spot for perfect positioning

- One-click certified reports – printable or PDF with your logo, date, serial number, and photo

- Zero daily maintenance – auto-calibration in 20 seconds

Perfect for:

- High-street jewelry stores

- Cash-for-gold & pawn counters

- Bank gold loan desks

- Small refineries and hallmarking centers

- Mobile buyers and traveling appraisers (optional carrying case)

Key Technical Advantages

- Latest-generation Silicon Drift Detector (SDD)

- High-stability ceramic X-ray tube (50 kV)

- 5 mm / 3 mm / 1 mm switchable collimators for tiny details

- Large 10-inch touchscreen + physical buttons (gloves-friendly)

- Wi-Fi & LAN enabled – send results directly to phone or POS

- Radiation safety: <0.1 μSv/h leakage – no special license required in most countries

Implementation Tips

Get your team testing like experts from day one – zero learning curve, maximum profit protection.

1. Physical Setup (5-minute rule)

- Place on a solid, non-vibrating counter (away from polishing motors or stamping machines).

- Keep 20 cm free space behind for ventilation.

- Plug into a dedicated power outlet with surge protection – no extension cords.

2. First-Time Calibration (Do this once, takes 2 minutes)

- Turn on → insert the factory calibration block (silver + gold reference).

- Press “Auto Calibration” → done. Repeat every morning (20 seconds) for guaranteed 99.99% accuracy.

3. Daily Workflow That Wins Customers

- Greeting → weigh item → place in chamber → close door → press “Start” → 30 seconds later → show customer the certified result on screen.

- Print or email the report with your shop logo – customers love the “lab certificate” and pay better prices.

4. Testing Different Items – Pro Tricks

| Item Type | Best Practice |

|---|---|

| Rings & earrings | Use the small 1 mm or 3 mm collimator + camera view |

| Chains & necklaces | Lay flat, use protective film to avoid tangling |

| Gold bars & coins | Center perfectly – use 8 mm collimator |

| Plated or filled items | Turn on “Coating Mode” – instantly shows base metal |

| Scrap & filings | Fill sample cup ¾ full, cover with thin film |

5. Staff Training (Under 30 Minutes)

- No science degree needed – train cashiers, security guards, or new hires in one short session.

- Use Napco’s built-in tutorial videos (English + 10 other languages).

- Let them test 10 real items – confidence skyrockets.

6. Integration & Compliance Hacks

- Connect to Wi-Fi → results auto-save to cloud.

- Export to Excel or your POS system via USB.

- Add your shop logo once → every report comes out branded and professional (perfect for bank loans or insurance).

7. Maintenance = Almost Zero

- Weekly: wipe chamber with alcohol cloth.

- Yearly: Napco remote health check (free for first 2 years).

- Tube and detector last 8–12 years under normal use.

Start making more money and losing zero grams from day one.

Overview & Challenge

How the Precious Metals Industry Operated Before Napco XRF

For decades, jewelry stores, pawnshops, banks, and refineries relied on outdated, risky, and painfully slow methods to determine gold and precious metal purity:

| Traditional Method | The Hidden Problems (The Challenge) |

|---|---|

| Acid scratch test | Destructive, damages jewelry, inaccurate beyond 2–3 karats, misses plating and modern counterfeits |

| Touchstone + magnet | Subjective, easily fooled by tungsten, cadmium, or thick plating |

| Fire assay | Takes days to weeks, expensive lab fees, destroys the sample, impractical for daily transactions |

| Cheap handheld “gold testers” | Drift after months, poor repeatability, cannot detect rhodium plating or iridium inclusions |

| Density/water displacement | Cannot distinguish real gold from tungsten-filled bars, useless for finished jewelry |

Real-world consequences businesses faced every day:

- Tens of thousands lost yearly on plated or counterfeit pieces that slipped through

- Angry customers when jewelry was scratched or damaged during testing

- Rejected bank loans and insurance claims due to lack of recognized certificates

- Inconsistent valuations between branches or staff members

- Regulatory fines for poor KYC/AML documentation on high-value purchases

The Napco XRF Solution – The New Industry Standard In just 30 seconds, non-destructively, and with 99.99%+ laboratory accuracy, Napco XRF analyzers (NAP-8200E, N1-25, N1-10, Mark Series) instantly reveal the exact elemental composition and true karat value of any item — eliminating guesswork, fraud, and financial risk forever.

From reactive damage and loss → to proactive precision and profit protection.